ABGS Precision Injection Mould

Product Details:

| Place of Origin: | Dongguan China |

| Brand Name: | GT |

| Certification: | ISO 9001 , IGS |

| Model Number: | Precision Injection Mould |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 mold |

|---|---|

| Price: | Negotiate |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

|

Detail Information |

|||

| Mold Type: | Precision Injection Mould | Runner: | Cold / Hot |

|---|---|---|---|

| Design Software: | UG , PROE , CAD | Plastic Material: | PP, PC , PS , PE |

| Mould Material: | H13 , 2738 , S136 , SKD61 | Mould Base: | Futaba , Lkm , Hasco , Dme |

| Cavity: | Single Mould | Tolerance: | Up To 0.01mm |

| Highlight: | H13 Precision Injection Mould,ABGS Precision Injection Mould,ABGS precision plastic injection |

||

Product Description

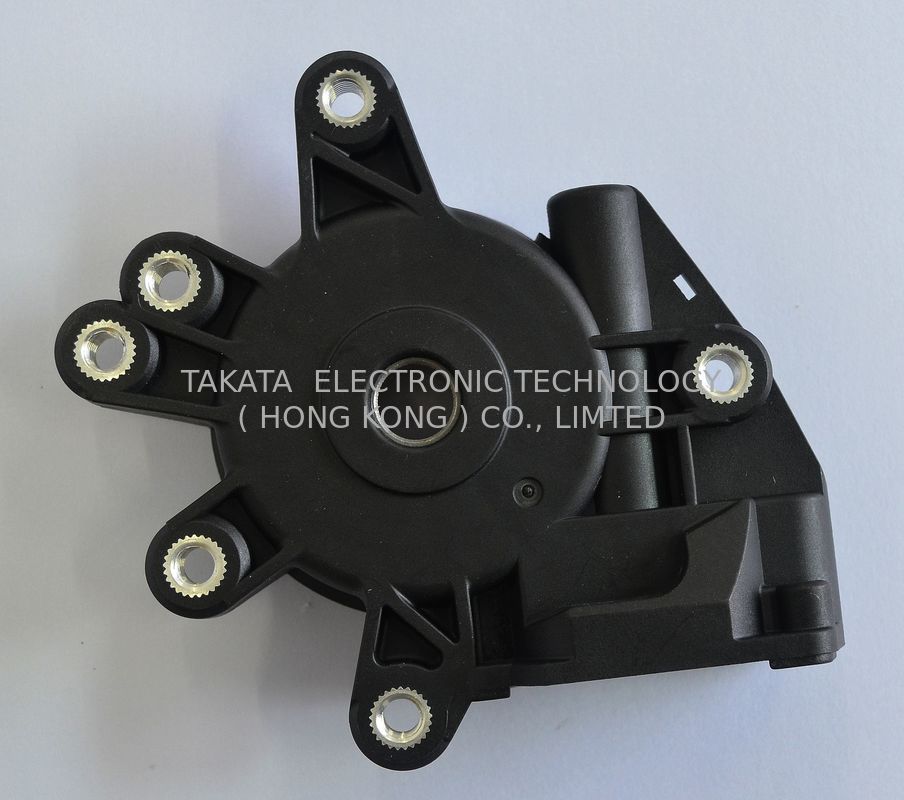

Custom Made Gear Box Pc Pvc Abs Precision Injection Mould

The mould has many inserts and slides, so it is a very high precise and

complicated electronic plastic frame mould, the logo and font are produced from the mould cavity.

Description:

| Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc. |

| Mould base | LKM, HASCO etc. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Design software | UG, PROE, CAD, CAXA etc. |

| Plastic material | PP, PC, PS, PE, PU, PVC, ABS, PMMA etc. |

| Mould life | 300,000-3,000,000 shots |

| Delivery time | 15-60days |

| Specification | Depends on customer's requirements |

| Mold doff way | Doff plate, ejectors, air valves, hydraulic jar, etc |

| Mold hot treatment | Including quencher, tempering, etc |

| Mold cooling system | Water cooling or Beryllium bronze colling, etc |

Applications:

The mould is made with many complicated slides and inserts.We can customize diverse moulds for our clients based on the 3D drawing they provide, such as the electronic part mould, plastic injection mould, die-casting mould and so on.

Specifications:

1. Quote competitive price according customer detail requirement

2. Sign agreement.

3. Customer T/T deposit to us to design mould

4. Send mould drawing to customer for confirmation

5. Mould design confirmed and start to make mould.

6. Make mould trial during tooling time(which we get agreement with customer).

7. Seed mould trial sample to customer for inspection.Or customer come to our factory to inspect mould

personally.

8. Customer T/T balance to us after mould confirmed.

9. Deliver mould after get balance.

|

Processing name:

|

Plastic Injection Mold

|

|

Master model making:

|

CNC machining,3D printing, prototype model etc.

|

|

Material of mold:

|

Steel

|

|

Material of products:

|

Plastic:ABS,PMMA,PA,PP,POM,RUBBER etc.

|

Ompetitive Advantage:

1. We keep long term cooperation with some world Top Brand on electronic product area, such Epson,

Canon and Sony.

2. We have successfully gained the quality certificate of ISO 9001 and IGS.

3. We can design and manufacture the mould in different specification and standard, such as DME,HASCO

and DAIDO.

4. The factory is well equiped with the most advanced testing instrument, it is effective to ensure the precision

of the mould.

5. Strict quality control;

6. Good After-sale service;

7. On time delivery

Packaging & Delivery

Packaging DetailsRegular Packing: OPP Bag + Outer Carton .

According to Customer ' s Requirement: Customized packaging/Package .PortShen Zhen Port or Hong Kong PortLead Time : Quantity(Sets)

our service

We can tailor various kinds of Plastic mould for each customer as per their requirements. The quotation can

be made based on drawings or samples provided by the customers. Our products are both excellent in quality

and reasonable in price. Your satisfaction is guarantee.

![]()