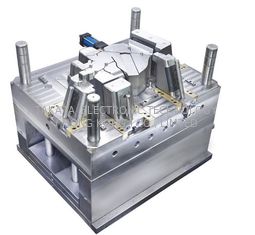

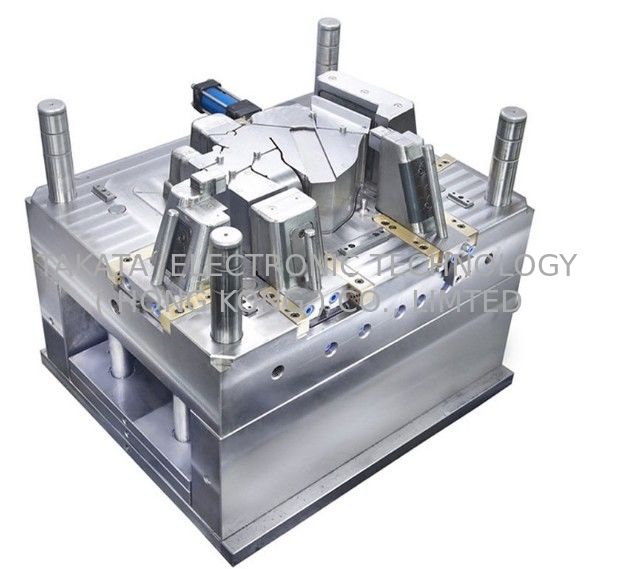

500000 Shots Injection Molding Mold

Product Details:

| Place of Origin: | Dongguan China |

| Brand Name: | GT |

| Certification: | ISO 9001 , IGS |

| Model Number: | Plastic Injection Mold |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 mold |

|---|---|

| Price: | Negotiate |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

|

Detail Information |

|||

| Key Words: | Plastic Injection Mold | Mould Life: | 250000-300000shots |

|---|---|---|---|

| Design Software: | UG , PROE , CAD | Plastic Material: | PP, PC , PS , PE |

| Mould Material: | H13 , 2738 , S136 , SKD61 | Mould Base: | Futaba , Lkm , Hasco , Dme |

| Drawing Format: | Stp , Step , Dwg , Stl | Tolerance: | Up To 0.01mm |

| Highlight: | 500000 Shots Injection Molding Mold,SKD61 Injection Molding Mold,SKD61 precision injection molding |

||

Product Description

Custom Make Plastic Injection Molds / Mould Life > 500000 Shots

Each customer has a different set of requirements necessary for a successful custom plastic program launch and we work diligently to find precise solutions. Our organizational structure combines our sales, engineering, tooling, and production teams, which results in a team oriented culture. We work quickly to find high quality solutions and share a drive for excellence.

We has a series of advanced equipments including Fanuc CNC machines, Sodick EDM machines, Sodick wire cut machines, Okamoto grinding machines, Haitian Injection molding machines, Zeiss CMM, Easson 2D projector, and iMould Automatic System. We make full dimension measurements for all mould components, copper and parts.

Specifications:

1. Quote competitive price according customer detail requirement

2. Sign agreement.

3. Customer T/T deposit to us to design mould

4. Send mould drawing to customer for confirmation

5. Mould design confirmed and start to make mould.

6. Make mould trial during tooling time(which we get agreement with customer).

7. Seed mould trial sample to customer for inspection.Or customer come to our factory to inspect mould

personally.

8. Customer T/T balance to us after mould confirmed.

9. Deliver mould after get balance.

| Mould Type | plastic injection mould manufacturer |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Mould Material | 718H, P20, NAK80, S316H, SKD61, etc. |

| Hardness of the steel | 20~60 HRC |

| Mould Base | HASCO, DME, LKM, etc. |

| Runner | Hot runner, Cold runner, as per customers requirementand part structure. |

| Mould Cavity | Single-cavity or Multi-cavit, as per customers requirementand part structure. |

| Ejection Techniques | Pin ejection, sleeve ejection, bar ejection, blade ejection, etc. |

| Gate Type | Edge gate, sub-gate, pin gate, side gate, etc. |

| Mould hot treatment | Quencher, Nitridation, Tempering, etc. |

| Mould cooling system | Water cooling or Beryllium bronze cooling, etc |

| Mould Surface | EDM, texture, high gloss polishing |

| Mould Life | >500,000 shots |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

| Raw material of plastic injection | PP, PA6, PLA, AS, ABS, PE, PC, POM, PVC, PET, PS, TPE/TPR, etc. |

| Lead Time | 25~60 days |

| Certificate | ISO 9001:2015 |

Professional Team

1. Our team has strong energy and capability to help you achieve your idea: design-production-surface

treatment-assembly-package-shipment, etc.

2. Skilled designer with related software (CAD, UG, PRO-E, Solidworks, Catia, etc.) can draw your products.

3. Professional knowledge will solve every difficult problem.

4. With strong responsibility and good communication to reach high efficient and accurate work.

5. Excellent team work will meet your various requirements.

![]()