GT Magnesium Alloy Precision Plastic Injection Moulding

Product Details:

| Place of Origin: | Dongguan China |

| Brand Name: | GT |

| Certification: | ISO 9001 , IGS |

| Model Number: | Precision Injection Mould |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 mold |

|---|---|

| Price: | Negotiate |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

|

Detail Information |

|||

| Key Words: | Precision Injection Mould | Runner: | Cold / Hot |

|---|---|---|---|

| Design Software: | UG , PROE , CAD | Plastic Material: | PP, PC , PS , PE |

| Mould Material: | H13 , 2738 , S136 , SKD61 | Mould Base: | Futaba , Lkm , Hasco , Dme |

| Cavity: | Single Mould | Tolerance: | Up To 0.01mm |

| Highlight: | Magnesium Alloy Precision Plastic Injection Moulding,GT Precision Plastic Injection Moulding,GT precision plastic injection |

||

Product Description

project engineer manager service

The Project Manager is responsible for the project from initial discussions with customer representatives

until the project is successfully completed. For the customer this means: One Project – One Contact.

The Project Engineer is responsible for the technical side of each project. He delegates the work to the different departments and is in close contact with the Project Manager.

The customer gets weekly updates about the project status.

Advantages:

1. Competitive Price

2. Quick Delivery time(2-4 weeks)

3. ISO Certificated with the srtictest quality control system

4. 23 Years OEM&ODM Mould-making and Plastic processing experience

5. Advanced equipment and Skilled workers

|

Product Name

|

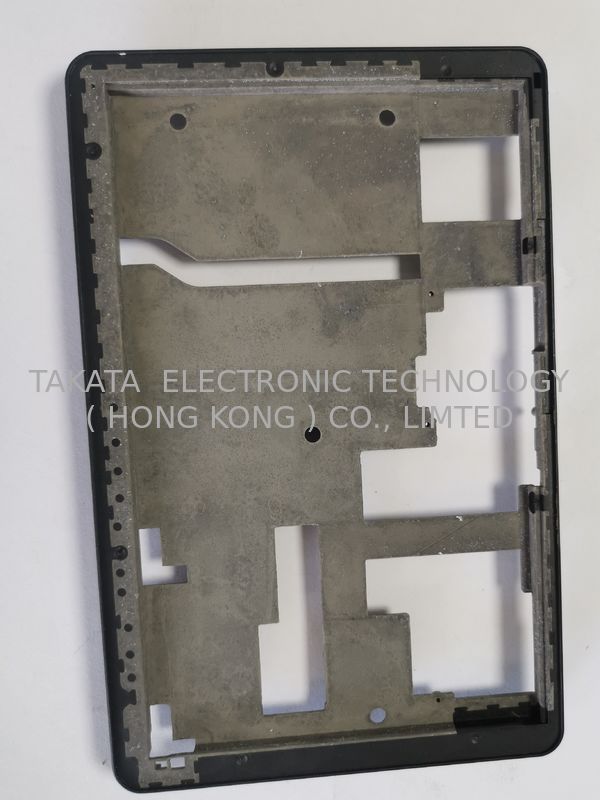

Custom Made Magnesium Alloy Phone Case Precision Injection Mould | |||

|

Application

|

Auto Parts, Home Appliance, Medica Equipment, Household Product, Electronical Parts, etc.

|

|||

|

Mold Base

|

LKM, HASCO, DME, etc.

|

|||

|

Mold Steel

|

NAK80, ASSAB8407, S136, 718H, 738H, etc.

|

|||

|

Mold Cavity

|

Single cavity mold or Multi cavities mold

|

|||

|

Tolerance

|

+/-0.002mm

|

|||

|

Finish

|

Polish, Silk Screen, Painting, etc.

|

|||

|

Sprue Gate

|

Hot runner, Cold runner, Tunnel gate, Pin point gate, sub-gate, etc.

|

|||

|

Drawing format

|

STEP/STP/IGS/CAD/PDF/DWG/STL,etc.

|

|||

|

Product Resin

|

PC, ABS, PP, POM, PBT, NYLON, PMMA, TPE, TPU, SAN, etc.

|

|||

|

Mold Life

|

100K - 1.5M

|

|||

|

T0 Lead Time

|

20 days - 45 days

|

|||

|

Transportation

|

By sea, by air, by land or train as your instruction

|

|||

|

Package

|

YF mold standard package based on different transportation way or as your instruction

|

|||

|

Ship Condition

|

Ex work, FOB or to be negotiated

|

|||

|

Certificate

|

ISO 9001:2015

|

|||

|

OEM/ODM

|

YES

|

|||

1). Professional mold design as the production mould standards

2). Professional mold assembly staff with over 9 years experience

3). 2-shift fast manufacturing with CMM testing for each machining processes

4). Clear project schedule plan and on time delivery

5). Professional project management with efficient communication to make every minutes counts.

Specifications:

1. Quote competitive price according customer detail requirement

2. Sign agreement.

3. Customer T/T deposit to us to design mould

4. Send mould drawing to customer for confirmation

5. Mould design confirmed and start to make mould.

6. Make mould trial during tooling time(which we get agreement with customer).

7. Seed mould trial sample to customer for inspection.Or customer come to our factory to inspect mould

personally.

8. Customer T/T balance to us after mould confirmed.

9. Deliver mould after get balance.

We can tailor various kinds of Plastic mould for each customer as per their requirements. The quotation can

be made based on drawings or samples provided by the customers. Our products are both excellent in quality

and reasonable in price. Your satisfaction is guarantee.

![]()