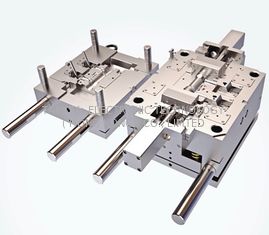

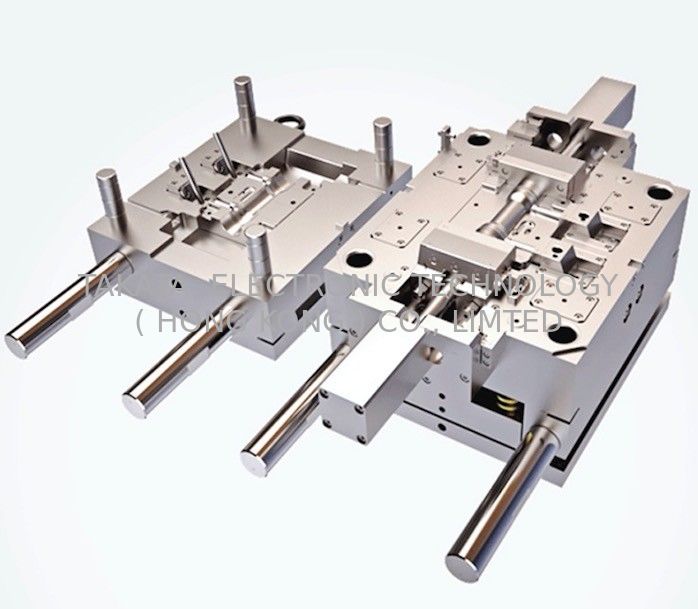

Die Casting ISO9001 2015 AlSi9Cu3 Metal Stamping Mold

Product Details:

| Place of Origin: | Dongguan China |

| Brand Name: | GT |

| Certification: | CE / ISO9001 |

| Model Number: | Metal Stamping Mold |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 mold |

|---|---|

| Price: | Negotiate |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

|

Detail Information |

|||

| Mold Base: | LKM C50 + P20 For AB , Cast Iron Etc | Product Material: | Aluminium , ADC12 , ADC14 , A360 , A380 , AlSi9Cu3 And So On |

|---|---|---|---|

| Shape & Color: | Can Be Design According To Your Needs | Model: | Sheet Metal Stamping Molds Tool And Die Makers |

| Item Name: | Metal Stamping Mold | Certificated: | ISO 9001:2015 Certificated |

| Shaping Mode: | Die Casting | Mold Treatment: | Heat Treatment >HRC45 |

| Highlight: | ISO9001 2015 Metal Stamping Mold,AlSi9Cu3 Metal Stamping Mold,AlSi9Cu3 custom metal molds |

||

Product Description

Our service

1. Delivery

By air, by express (By UPS/DHL/FEDEX/TNT) or by sea, all available.

2.OEM service

We offer OEM services.

3.Payment term

Normally T/T. L/C is also accepted if the order quantity is large.

4.Shipping port

Shenzhen

5.Discount

Discounts can be offered based on order quantities.

6.Samples

We can send you some free samples for your test before your order. You just bear the freight.

Mould Main Features

1.The moulds that we design and produce are suitable for almost every kind of machine or press.

2. We produce mould with the best quality steel in China. And some main mould areas are made high-temperature heat treatment for proper hadness, which ensure moulds are in great quality and long life.

3. To meet customers’ different requirement, we design and manufacture the mould in several rims, such as G rim, L rim, H rim, and IVC etc.

4. We can design and produce the mould in multi-cavities, no matter it is one compartment container or multi-compartments container.

5. In order to save foil material cost, we has innovated “zero-web" moulds. This kind of mould will reduce lots of foil scrap.

|

injection molded parts Description

|

|||||||

|

Design software

|

UG, ProE, Auto CAD, Solidworks, etc.

|

||||||

|

Certificate

|

ISO 9001,ISO14001,OHSAS18001,IATF16949

|

||||||

|

Plastic production

|

PP,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR, silicone rubber,etc

|

||||||

|

Raw material

|

(flame retardant, UV as optional)

|

||||||

|

molded parts size

|

As per your drawing or samples

|

||||||

|

Color

|

According to your Panton number color or your samples

|

||||||

|

parts finish

|

painting, chrome, silk sreen, thermo printing, etc.

|

||||||

|

Molded Parts features

|

Free of flash, sink mark, blemishes, variation, etc.

|

||||||

|

Parts application

|

Medical, automotive, industrial, electronics, security, home appliances

|

||||||

|

lead time

|

1 week

|

||||||

|

Packing

|

bulk or individual pack, upon customer's demands with exported carton box.

|

||||||

Basic information:

| Brand | Moldie |

| Mold Base | LKM C50 + P20 for AB, Cast iron etc. |

| Inserts(cavity and core) | Dievar, H13, 8407, 1.2344 or the material you required |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Material | ADC12, ADC14, A360, A380, AlSi9Cu3 and so on |

| Mold Treatment | Heat Treatment >HRC45 |

| Product Surface | Sand blasting, Powder coated, Painting, Anodizing, etc |

| Shape & Color | Can be design according to your needs |

| Process | High Pressure Die Casting |

| Certificated | ISO 9001:2015 Certificated |

Advantage

2. Suitable for materials that are difficult to process.

3. Quick installation system can not only reduce the time to install the mold, but also reduce the damage rate of the mold

4. Usually, multiple air holes are embedded in the product, and the visible density is lower than the true density, which reduces the weight of the product.

5. Use lubricating oil by using air holes. No oil supply is required.

A1: We are manufacturer.

Q2: Do you provide free samples ?

A2: Yes, We provide samples.

Q3: How about the quality?

A3: We have the best professional engineer and strict QA

and QC system.

Q4: How’s the package?

A4: Normally are cartons, but also we can pack it according

to your requirements.

Q5: How’s the delivery time?

A5: It depends on the quantity you need, 1-25 days usually.