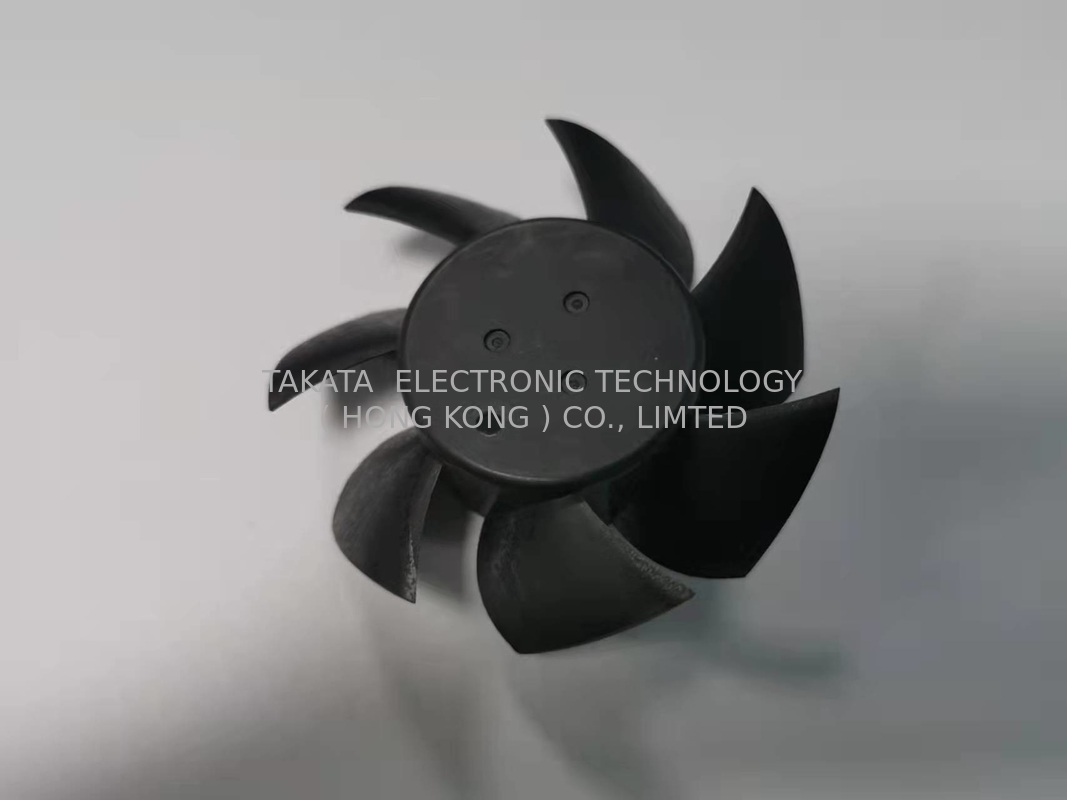

Cosmetic Fan Blade Injection Molding Mold Using SKD61 Material

Product Details:

| Place of Origin: | Dongguan China |

| Brand Name: | GT |

| Certification: | ISO 9001 , IGS |

| Model Number: | Plastic Injection Mold |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 mold |

|---|---|

| Price: | Negotiate |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

|

Detail Information |

|||

| Mould Life: | 500000 Shots | Design Software: | UG , PROE , CAD |

|---|---|---|---|

| Plastic Material: | PP, PC , PS , PE | Mould Material: | H13 , 2738 , S136 , SKD61 |

| Mould Base: | Futaba , Lkm , Hasco , Dme | Tolerance: | Up To 0.01mm |

| Highlight: | 500K shots Injection Molding Mold,Cosmetic Fan Blade Injection Molding Mold,SKD61 Material Plastic Injection Mold |

||

Product Description

Cosmetic Fan Blade Injection Molding / Injection Molding Mold

|

Main Product

|

CNC processing, plastic molds/molds, prototypes, injection molding products,

two-color injection molding, plastic products,secondary molding,3D printing, such as automotive plastic parts, electronic plastic parts, home parts and other parts. |

|||

|

Mould Material

|

P20/718/738/NAK80/S136/2738/2316/H13, etc.

|

|||

|

Moud Precision

|

+/-0.01mm

|

|||

|

Mould Life

|

50K-5000K shots

|

|||

|

Mould Cavity

|

Single cavity, multi-cavity

|

|||

|

Runner System

|

Hot runner and cold runner

|

|||

|

GateType

|

Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc.

|

|||

|

Equipment

|

CNC,EDM, 3 d coordinate measuring instrument,Machine,plastic machinery,etc plastic part

|

|||

|

Plastic Material

|

PA6,PA66,ASA,POM,PPS,ABS,ABS+GF,ABS+PC,POM(Derlin),PP,PE,PC,

PMMA(Acrylic),PVC,PEI,PBT,PTFI |

|||

|

Surface Treatment

|

Polishing,Painting,Chroming,Anodizing, Brushing, Silk Screening,Water Transfering, Laser Cutting,Leather

Covering,Texture,Sanblasting,Gilding, UV Painting… |

|||

|

Pls Provide

|

2D, 3D, samples, or the size of the multi-angle pictures

|

|||

|

We Promise

|

All in the interests of the customer,Tell me what you want and we will do the rest.

|

|||

High quality gurranteed

- Material strictly as required and can provide material certificate

- Precision machining process with a good control of tolerance

- High quality surface treatment

- 100% inspection before shipment,test report of final products can be provided.

Over 10 years experience only for LSR mold, Compression Mold, Rubber Injection Mold, Transfer Mold design & mold making.

We offer multi-material mold, liquid silicone rubber mold, high-performance multi-cavity mold and precision inserts mold , with international standards. materials and how turntable control systems, liquid silicone rubber (LSR) cold runner systems

OEM & ODM

We have a lot of molding machines, and can provide products OEM / ODM service

Maturity technology for multi-color molding, over molding(P + R/metal+R), and over molding other composite materials, some projects fully automated production molding without flash.

Why Choose Us As Your Mold Supplier?